Oil & Gas

Power Generation

Petro Chemical

Mining / Construction

General Maintenance

Military

INDUSTRIAL SERVICES

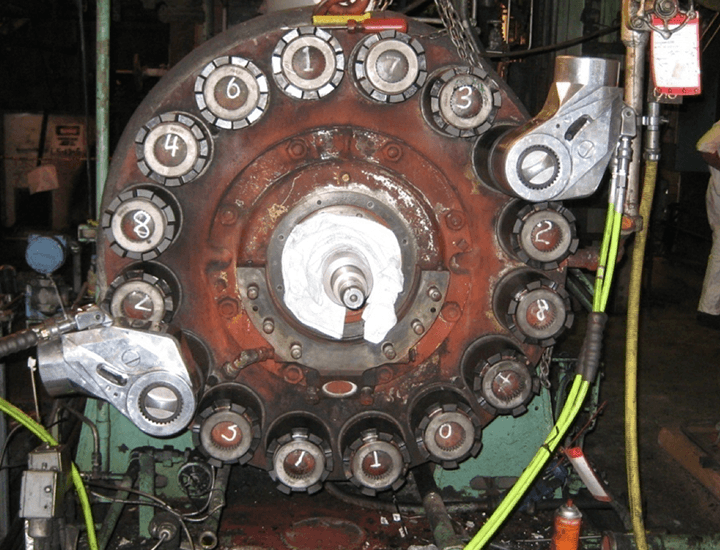

BOLT TORQUING AND TENSIONING

ON SITE & IN SITE MACHINING SERVICES

Flange facing. (¾ ”- 120”)

Pipe cutting & end bevelling.(1”- 90”) Milling and key cuttings.

Drilling, boring and tapping etc.

POWERTORC is doing flange facing from size ¾” to 120” flanges with a finished machining surface being flat, spigotted, raised face or ring grooves with a finished machining surface from fine gram phone (CLA 6- CLA 2000). And in Pipe cutting & end bevelling we have a range from 1”- 90” .Our combination of knowledge, skill, fast response, realistic pricing and above all the ability to get the job done without compromising the quality make us one of the fastest growing specialist in site machining services companies in the Kingdom.

CHEMICAL CLEANING

HYDRO JETTING / PIPE CLEANING

Hydrotesting, Pigging & Decruding

The services includes Hydro test / Pigging /

Chemical Cleaning of:

- Pipe lines.

- Heat Exchangers.

- Vessels.

- Spools.

- Valves. We have calibrated equipment’s from reputed brands with qualified, trained, experienced technicians under experienced supervisor to undertake such jobs.

We are giving these machines on rental basis

Inline Testing

When a new flange has been welded to a pipeline, traditionally the method used to prove the integrity of a weld would involve flooding the pipeline in order to hydrostatic test.

Flange test overcomes this problem as it isolates the testing area, this, reducing time and resources required.

The flange weld tester can be used on pipes size ranging from 1/2” to 52” and pressure rating for all classes starting from 150#.

POWERTORC Location (India):

Office No.201, Gera's Park View Plaza, Behind Eon IT Park, Kharadi 411014

Ph: 0091-20-42005053

BOLTING INTERGRITY SOLUTION

POWERTORC Location (USA):

27 Amelia Ave.,Livingston,

NJ,07039 USA

Ph: (001)-(1800)-6836983 BOLTING INTERGRITY SOLUTION

Ph: (001)-(1800)-6836983 BOLTING INTERGRITY SOLUTION

Copyright © 2019

POWERTORC Corporation